BIPV

Authors: C. Polo Lopez, P. Bonomo

SUPSI-ISAAC, Campus Trevano, CH 6952, Canobbio, Lugano, Switzerland

The BIPV market in Europe is in a transition. The past decades of a slowly emerging BIPV market have been characterized by the original dominant value of BIPV: a building that communicates an image of sustainability and innovation. Payback time or returns on investment have not been the major parameters in the decision process for applying BIPV, as well as for conventional building products. The technological transfer of PV in the architecture field is changing design approaches and opening new challenges. Energy performance regulations are taking over as the main driving factor for the BIPV market. With the recast of the Energy Performance of Buildings Directive (EPDB 2010) [1], which states that each new building should be made ‘nearly zero energy’ from 2020 onwards, high energy performance buildings are called to generate enough energy to balance their energy consumption, covered in a large extent by energy from renewable sources produced on-site (see an example in Figure 1).

Figure 1: Positivo-Gasser Building, Plus Energy multi-family House, Chiasso (CH). Swiss solar prize 2014. The building is refurbished with the re-cladding of the existing skin through a ventilated cold façade, made active with PV on the whole building envelope. Additionally, solar semitransparent PV modules were used in balconies and additional BIPV systems are used on the roof (Source: SUPSI-ISAAC, www.bipv.ch)

To be attractive and competitive, photovoltaic solutions for the building sector, have to be “integrated” and “transformed” to fit the architect’s needs, also through a harmonized regulation. Today, a new reference standard [2] defines the general requirements to be met by these types of products in the perspective that BIPV is a construction product. The industry already makes available a plenty of products for building application: multi-functionality, cost-effectiveness, mass customization and other paradigms are ensuring a growing penetration of the technology. Beyond functional and construction aspects, definitely BIPV is today one of the new fundamentals for contemporary architecture. BIPV is more and more a key driver for the PV market in Europe nowadays, as demonstrated in recent several pilot-projects, conducted in Switzerland and abroad, where it clearly emerges BIPV as a distinctive architectural solution (see Figure 2).

a)

b)

c)

Figure 2: Recent BIPV systems developed for façade solutions: a) Wohnhaus Solaris residential building, Zürich/CH, HUGGENBERGERF (source: HBF); b) Multi-family Plus Energy Building Hofwiesen - Rothstrasse, Zürich/CH (source: Viridén + Partner AG); c) Copenhagen International School, Copenhagen/DK (source: Swissinso SA).

1. BIPV current situation and market overview

The trends in BIPV market evolution among the last years have been stated investigated by different research studies and international reports, which reported about the main changes in the BIPV industry [3-5], the most common BIPV/BAPV systems used in buildings and pilot projects, together with survey for end-users and interviews with BIPV manufacturers [6].

1.1. BIPV market dynamics

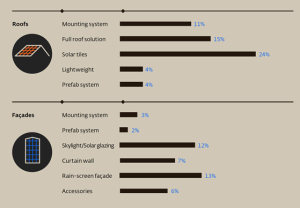

The market progression in last years registered a passage from BAPV/BIPV roof solutions (small and large solar tiles and full roof solutions) to façade solutions pointing out that there is an emerging market with a high potential. The Swiss BIPV Competence Centre ISAAC-DACD-SUPSI (www.bipv.ch) since many years collects a wide database of existing and commercially available products [7] and conduct research and industry surveys to follow the main tendencies of the BIPV market [8, 9]. Since 2015, SUPSI published periodically each two years a Status Report on BIPV product portfolio in Europe, a joint publication with the Solar Energy Application Centre (SEAC). In the last version published in September 2017 [10], a comprehensive overview of commercially available BIPV systems for buildings in the European market was supported by more than 100 suppliers. The study reveals that the roof market is still currently bigger than the façade market (see Figure 3). The most common product group is solar tiles (14%) followed by the full roof solution or totally integrated system (15%) and mounting systems, BAPV or partially integrated system (11%). However, BIPV systems for façades are the runner up (e.g. products for rain-screen façades reach 13%, and skylight / solar glazing reach slightly less percentage rate 12%) and they are expected to gain importance. Furthermore, prefabricated systems, although the strong growth with respect to previous studies [11] still remain a niche market (4% on roof and 2% for façade solutions). The market share of thin film products for roof (8%) has been significantly reduced in recent years due to the decreasing of crystalline silicon prices. By contrast, it was found that 44% of the BIPV available products for façades use thin film technology. Façade solutions can be customized solutions made by glass-glass modules, including dummies and special pieces.

Figure 3: Distribution of listed products according to the different categories. Results of the market survey presented in terms of the occurrence of product groups [10].

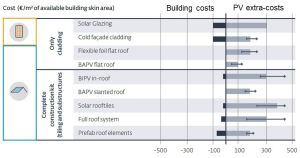

Although there is a significant price range for the different conventional roofing/façade materials commonly used in architecture, the BIPV market survey has pointed that extra-costs for a BIPV roof system varies between 100–300 €/m2 (>200-600%) with regard conventional building products (e.g. a tiling). This means that an active roof has a significantly higher extra-cost compared to a BIPV façade system that in many cases can be cheaper than a conventional façade solutions with an extra-cost varying in a range of 50–300 €/m2 (>20-40%), as seen in Figure 4. Thus a façade BIPV system becomes cost-effective in most of cases when BIPV replaces conventional building cladding elements (curtain wall, marble, etc.) and it can be demonstrated taking into account the whole building envelope system. Of course the design, and consequently the required manufacturing efforts, can affect the cost of the cladding las it happens for conventional building façade (e.g. prefab elements or integrated solutions allow optimizing not only the final cost, but also the timing and the complexity of the installation).

Figure 4: Cost analysis survey conducted mainly for the Dutch/Benelux and Swiss market as resulted from SUPSI-SEAC survey [10]. Black bars represent the costs avoided because no conventional building material is used. Grey bars represent the additional costs to apply PV in the building skin. The total cost results from the sum of both. The error bars show the full range (min-max) of all the different quotes.

Figure 4: Cost analysis survey conducted mainly for the Dutch/Benelux and Swiss market as resulted from SUPSI-SEAC survey [10]. Black bars represent the costs avoided because no conventional building material is used. Grey bars represent the additional costs to apply PV in the building skin. The total cost results from the sum of both. The error bars show the full range (min-max) of all the different quotes.

It is clear that BIPV market is dynamic and many products appeared on the market within the last two years. New research efforts on BIPV nowadays focus on developing innovative performant, aesthetic and cost-effective solutions to provide the market with available products. Multi-functionality, cost effectiveness, mass customization and other paradigms are ensuring a growing penetration of the technology itself, but beyond functional and energy aspects. BIPV is slowly becoming part of the architectural concept. It is our expectation that in the next few years more prefabricated PV products, coloured PV products, semi-transparent PV products and lightweight PV products will have entered the market. Many attractive products are available, reliable and offered at a competitive price. Examples of aesthetically pleasing and affordable BIPV buildings can be found and are more and more entering the ordinary building stock.

To envision new markets concerning the integration of BIPV in the building environment, as construction element, the further requirements that should be addressed in next future are the durability, safety, reliability and maintenance together with low environmental impacts. This calls to an important bridge between building and PV specialisms.

Other key factors for the future development of the BIPV market, will be: 1) the value-chain of an integrated approach since early design process to support product and process innovation considering long-term new materials and solutions to achieve low production costs; 2) the right balance between customization and standardization without forgetting the importance of the “integration type” on energy performances; and finally; 3) a special focus on innovative design and more aesthetically attractive BIPV solutions that will allow some niche markets today definitely to take off.

2. New trends for BIPV technological systems

New manufacturing possibilities that are changing the PV component from an electrical device to an architectural tailored element represent one of the main BIPV technological trends which are more and more opening the research field to the investigation of new operating conditions and energy behavior of BIPV systems. Different operating conditions from conventional PV as function of different building skin scenarios, colors or non-homogeneous surface treatments are just some examples. This document summarizes the main trends today leading new developments for the PV industry.

The process of product innovation in BIPV industry is today mainly linked to the integration of architectural image and construction technology in PV products. As stated in different studies [12, 13] new technologies are constantly increasing the generation efficiency improving the return on the investments in BIPV where a high priority and challenge is to achieve cost competitiveness and similar prices to conventional building products, for large deployment in the construction sector. Innovative BIPV solutions are being developed, not only to ensure adequate performances satisfying functional and safety qualities, but mainly to achieve a valuable architectural design with solutions, as similar as possible, to other conventional building products.

2.2. Invisible “PV”, a technology ready for the market

In recent years, the transition of the BIPV market have been leaded by new emerging trends for BIPV based on different customization possibilities, such as the new design scenario of a hidden (colored) or low-recognizable PV. Special treatments, colors or patterns applied to glass allow to mask solar cells and to mimic solar products with other similar products commonly used in construction, with not significant loss of electrical performance. This chromatic mimicry or technological mimicry applied to BIPV products is today possible thanks the mature design and qualification level for the building sector of solar glazing industry (e.g. safety glass, EU marking for CPR, mechanical and fire safety, etc.). In façade solutions, directly derived from already well-established building skin systems (e.g. curtain walls), the extra-cost of PV become less relevant. Many products are already being available but all implications (performances, proprieties, reliability, durability, lifetime, etc.) and PV energy outputs are still not well known and need to be further investigated [14].

Different solutions can be used to customize each layer of the photovoltaic module: e.g. by coloring the cells; by modifying or color the electrical contacts; by using glass treatments in the front rear; by printing the encapsulating material or by changing the back-rear substrate. As example, the terracotta PV tiles developed by Romag Ltd (Figure 5.a) has been designed with aesthetics in mind and blends seamlessly with black, grey and brown concrete and clay tiles concrete and clay tiles. A treatment based on Nano-inks to create new solutions introducing colors in glass products were used also in the Archinsolar project, the terracotta-red PV modules has been installed in Ecuvillens, a Swiss historic protected site. The new BIPV solution has been developed by CSEM (Swiss center for microelectronics and micro-technologies) in partnership with ISSOL (Figure 5. b) [15].

a)

b)

Figure 5: Tile-colored photovoltaic panels for roof applications: a) Terracotta Intecto solar roof tile (Source: Romang Roof Integrated Solar Tiles, http://www.romag.co.uk); b) Thin-film terra-cotta modules, Archinsolar Project and Pilot project with terracotta-red solar panels, Ecuvillens/FR Switzerland, Issol (Source: [15] CSEM http://www.csem.ch).

Advances in glass technology are used also in façade components to “camouflage” the PV cells using special colors, drawings, sketches or patterns to provide the PV solution with a new visual aspect multiplying design choices without significant power losses due the use of high efficiency of solar cells. Increasing building and urban quality to drive better acceptance by professionals and the public, overcoming also barriers to the integration of photovoltaic systems in historical heritage sites and city cores, is becoming real. Different techniques are used: a) anti-refection coatings on solar cells; b) intermediate foils with colors or patterns (e.g. high-resolution photos printed on a special film foil by using printing techniques from the graphical industry or semi-transparent inks that allow the infrared light to pass); c) special solar filters (e.g. selective optical filters with scattering properties or spectrally selective coatings); d) front-glass surface processing treatments (e.g. ceramic mass colored glass, satin finished and mineral coatings, sandblasting and digital printing techniques).

As example, KromatixTM technology developed by SwissINSO SA in partnership with EPFL (Swiss Polytechnic Institute), use a multi-layer reflective coating on the glass. The coloured coating is deposited on the front surface by chemical etching. Light transmission depends on color, varying from 90% to 85% compared to standard solar modules (see Figure 6).

Figure 6: Colorful custom-size solar panels for façades SwissINSO KromatixTM. Demonstration BIPV project “Kohlesilo”, Basel/CH. (Source: SUPSI http://www.bipv.ch/images/esempi/amministrativo/SolarSilo/SolarSilo_ENG.pdf)

Different surface treatments could be also applied on the front glass of BIPV modules. Multi-colors ceramic digital printing on BIPV glass consist on applying a ceramic paste to the glass prior tempering in order to allow additives bake out and the ceramic paste strongly bonds to the glass. An example developed by the Lucerne University of Applied Sciences ensures no partial shading and losses less than 20% [16]. Another special colored and textured BIPV cladding façade solution has been used by Huggenbergerfries Architekten Studio in the multi-family building Wohnhaus Solaris, as see in the introduction (Figure 2.a). Digital glass printing processes with special inks (e.g. EU project SmartFlex [17]) or with a satin matte finishing on the outer glass surface combined with silk-printing on the inner side, are other new developments that have been used in different pilot projects in Switzerland, as shown in the introduction (see Figure 2.b). Sandblasting is another technique to modify the front glass surface of BIPV modules that consists in spraying sand at high velocities, creating milky white patterns and sketches (e.g. innovative BIPV modules developed within the EU project ConstructPV [18], see Figure 7). Mineral coatings are used in commercially BIPV modules SUNCOL designed by Glassfer & Sunage that are available in five color variants (green moss, anthracite gray, light gray, terracotta and medium brown), both matt and polished. Most of these innovative BIPV solutions even if still in a prototyping stage are potentially ready to the market and have already been used in several demonstrative pilot projects

a)

b)

Figure 7: Construct PV FP7 Project: a) Small scale façade mock-up where different innovative BIPV systems variants (Source: SUPSI); b) Demonstrative building Z3 building-Stuttgart (GE), Zublin AG (Source: Construct PV EU research project [18], http://www.constructpv.eu/)

2.3. Prefabricated, multi-functional and lightweight BIPV components for building skin

BIPV manufacturing companies are facing intense competition from emerging markets, stricter standardization and regulations as well as changing customer/architects behavior and requirements. Successful companies focus on product value rather than merely on product costs by using innovation technologies and effective new product development methods in search of competitive advantage with improved functionalities, added values and superior product performances.

In recent years, in the BIPV market unitized and pre-assembled elements (Figure 8) to be directly used as roof or façade, represent a new trend that is being driven by a greater need for renovation of the real estate park and social housing renovation programs in several EU countries, and it is expected that prefab building further increasing the market potential in next years. Renovation process becomes faster and easier reducing labour cost. The objective is to reach greater product and process optimization towards mass-customization. In some available prefab systems, the whole process of design, manufacturing and implementation is performed industrially and it is possible customize colour, stratigraphy and thickness (e.g. insulation layer), dimensions, ratio transparency/opacity, indoor and outdoor final finishing, fixing and mounting system. In this case, as PV could be previously assembled and pre-wired in the entire building package the complexity and the cost could be reduced. In the same way, multifunctional/unitized “all-in-one” BIPV products, as polyvalent components able to satisfy more than a single technological requirement are gaining market.

a)

b)

Figure 8: Example of prefabricated and pre-assembled BIPV solutions: a) Face InTec Solar façade (Source: Face InTec, http://faceintec.com/en/solutions/); b) Multilayer BIPV component TCR 600 developed for pitched roofs (Source: Designergy SA. http://www.designergy.ch/index/).

Furthermore, new composite, customized and easy-mounting BIPV modules, such as lightweight products, rigid or flexibles, based on amorphous thin film silicon technology seems now show up again and recently crystalline silicon based ultra-lightweight PV panels are also emerging (some examples of existing products are shown in). Promising researches are working in this field on developing robust and reliable ultra-lightweight solutions by using polymer-bitumen membranes as back-sheet [19, 20] or metal-based back sheets made with aluminum, anodized aluminum, or steel [21] (see Figure 9).

a)

b)

Figure 9: New BIPV components based on polymeric or metal sheets as substrate: a) Solar shingle prototype developed by Tegola Canadese S.p.a (Source: Construct PV [18-20], http://www.constructpv.eu/ b) new lightweight solar modules developed by Flisom, within PVSITES research project (Source: PVSites [21], http://www.pvsites.eu)

Complexity of this type of products is greater and each layer can affect, both the building's energy exchanges (e.g. thermal insulation functions), and the performance of the BIPV module as the operating temperatures could be modified.

2.4. BIPV modules using bifacial cells

Bifacial PV modules can be used also as BIPV elements. Examples are the balconies or parapets, where it is possible to better exploit the double exposition of cells to enhance the final energy production. In some specific cases, this type of bifacial modules have been used as double skin façade (see Figure 10).

Figure 10: Bifacial modules as double skin cold façade installed at CSEM building, Neuchâtel/CH (Source: http://www.bipv.ch/images/esempi/amministrativo)

3. Outlook

A review of available BIPV products and innovative BIPV solutions expected to enter the market in the next few years has been here summarized allowing to spot realistic scenarios of future market evolution. Plenty customization possibilities are today possible to make the next generation of PV products even more affordable, aesthetical attractive, efficient, versatile and multifunctional, customizable and in compliance with standards and regulations regarding technical and functional requirements for construction products. This optimization process, where technological innovation must advance along with cost-effectiveness and reliability, implies improving product and process such as manufacturing, installation and O&M, working directly with the construction and PV manufacturing industry. Along with a constant product and manufacturing innovation, also new approaches focusing on the process optimization (an example, from construction industry is BIM, Building information Modelling) that can support the challenge of a massive transfer of PV in the building market to more efficiently plan, design, construct, and manage buildings and infrastructures, but also to integrate the custom-made BIPV new modules in the manufacturing process efficiently. In energy rating models, since now, BIPV systems are not yet considered with regard the possible interactions of the PV system with the building skin integration conditions that usually affect the PV power output and the energy behavior (e.g. roof and façade typologies, tilt and angle of slope, mounting and fixing elements, constructive package of the entire solution, transparency levels, unitized and prefabricated solutions or new materials, colors, textures or coatings, etc.). The interactions of the BIPV scenarios in the building skin, requires further detailed analysis to determine the main factors significantly influencing the energy yield.

Future research will have to investigate how these new approaches have to be considered in reference normative framework to properly analyze, test, validate and qualify BIPV products and systems since the BIPV non-conventional integration scenarios affect the PV energy behavior in different ways (electrical performance, operating conditions, temperatures, etc.). A first step would be to define reference scenarios for characterize and assess such effects, with the goal to optimize together aesthetics and energy aspects, by identifying the main requirements needed to describe and measure the performance of BIPV systems in building skin scenarios as well as the performance of special BIPV modules that are currently entering the market.

References

1. The European Parliament and the Council of the European Union, European Commission (2010): Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the energy performance of buildings (recast). 2010. pp. 13–35.

http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32010L0031, accessed on March 12th, 2018.

2. BS EN 50583-1:2016 - Photovoltaics in buildings - Part 1: BIPV modules; BS EN 50583-2:2016 - Photovoltaics in buildings - Part 2: BIPV modules.https://standards.globalspec.com/std/9984841/cenelec-en-50583-1, accessed on March 12th, 2018.

3. Cerón, E. Caamaño-Martín & F.J. Neila (2013). State-of-the-art of building integrated photovoltaic products. Renewable Energy 58 (2013). Pages 127-133.

4. C. Breivik (2012). Building Integrated Photovoltaics – A State-of-the-Art Review, Future Research Opportunities and Large-Scale Experimental Wind-Driven Rain Exposure Investigations. Civil and Environmental Engineering, June 2012. Norwegian University of Science and Technology. Pages 101

5. B. P. Jelle and C. Breivik, “State-of-the-Art Building Integrated Photovoltaics”, Energy Procedia, In press, 2012. Volume 20, 2012, Pages 68-77.

6. Kostas Sinapis, Menno van den Donker. BIPV Report 2013 State of the art in Building Integrated Photovoltaics. SEAC, Solar Energy Application Centre.

7. Swiss BIPV Competence Centre database of BIPV products (www.bipv.ch)

8. P. Bonomo, A. Chatzipanagi & F. Frontini (2015) Overview and analysis of current BIPV products: new criteria for supporting the technological transfer in the building sector. VITRUVIO, International Journal of Architectural Technology and Sustainability pp.67-85.

9. P. Bonomo et al. BIPV Products Overview for Solar Building Skin. Proc. 34th EUPVSEC Amsterdam, The Netherlands (2017)

10. Zanetti I., van den Donker M. et al. (2017). Building Integrated Photovoltaics: Product overview for solar building skins. Status Report 2017 SUPSI-SEAC, SUPSI, University, Lugano, Switzerland. Pages 71

11. C. S. Polo López et al. PV and Façade Systems for the Building Skin. Analysis of Design Effectiveness and Technological Features. Proc. 29th EUPVSEC Amsterdam, The Netherlands (2014), p. 3613 - 3618.

12. BIPV market and stakeholder analysis and needs - PVSites

13. E. Delponte et al. BIPV in EU28, from Niche to Mass Market: An Assessment of Current Projects and the Potential for Growth through Product Innovation. Proc. 31st EUPVSEC, Hamburg, Germany (2015). p. 3046 - 3050.

14. E. Saretta, F. Frontini & P. Bonomo (2016). Laminated BIPV glass: approaches for the integration in the building skin. In Engineered Transparency 2016: Glass in Architecture and Structural Engineering, p. 363 - 372.

15. ARCHINSOLAR, Unique and Innovative Solution of Silicon Thin-Film Modules for Building-Integration

16. S. Mertin et al. Coloured coatings for glazing of active solar thermal façades by reactive magnetron sputtering. Proceedings CISBAT 2011, Lausanne, Switzerland.

17. SMART-FLEX research project: Demonstration at industrial scale of the FLeXible manufacturing of SMART multifunctional photovoltaic building elements. Project ID: 322434. Funded by European Union's Seventh Framework Programme. FP7-ENERGY. Duration (from – to) 2013-11-01 - 2016-10-31.

18. PV CONSTRUCT research project: Constructing buildings with customizable size PV modules integrated in the opaque part of the building skin. European Union Seventh Framework Programme (FP7). FP7-ENERGY-2011-2, ENERGY.2011.2.1-4: Development and demonstration of standardized building components. Duration (from – to) 01.02.2013 – 31.01.2016.

19. C.S. Polo López et al. Outdoor Characterization of Innovative BIPV Modules for Roof Application. Proc. 32nd EUPVSEC, Munich, Germany (2016), p. 2770 - 2778.

20. C. S. Polo López et al. Performance assessment of a BIPV Roofing Tile in outdoor testing. Proc. 44th IEEE PVSC-44, Washington, D.C., June 25-30 (2017).

21. PVSites Building-Integrated photovoltaic technologies and systems for large-scale market deployment. European Union Horizon 2020 grant agreement No 69176.